Stream-Flo’s specialized and critical service wellhead equipment is designed and manufactured through close consultation with customers to meet their application’s specific requirements and service type. This includes specialized materials for sour service and CO2, corrosion resistant alloys (CRA), water flood, multiple completions, coiled tubing and instrumentation lines, and multi-bowl equipment.

Working pressures range from 2,000 to 20,000 psi and are designed for single or multiple completions. A significant inventory of conventional wellhead equipment is kept on hand to reduce lead times.

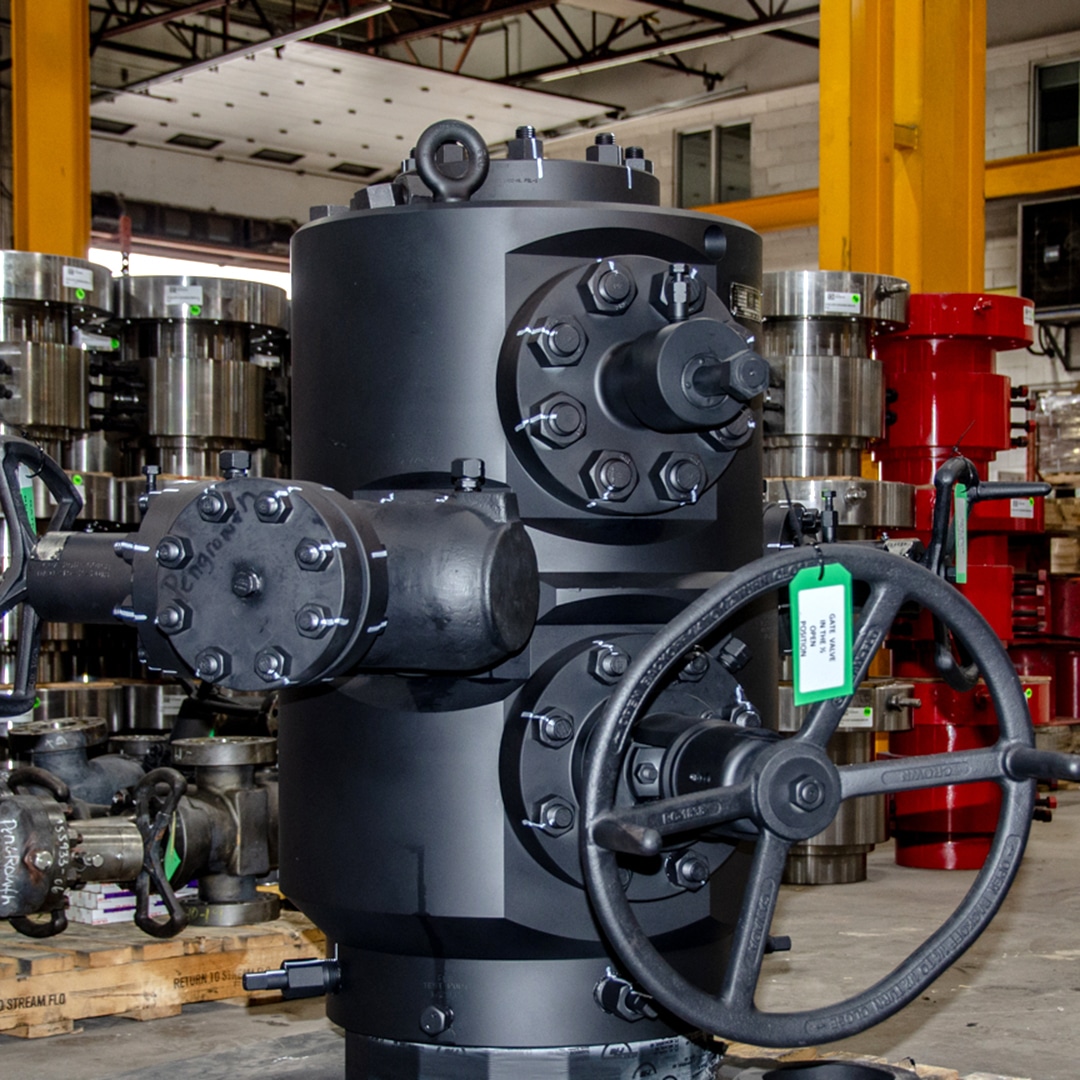

Our conventional wellheads include the Composite Pumping Tree (CPT), which was developed, introduced, and patented by Stream-Flo for rod pumping applications. The CPT combines the tubing head adapter, production blow-out preventer, pumping tee, and studded-top connection in one solid compact unit.

The result is a stable, secure product that provides distinct advantages over traditional pumping Christmas tree arrangements. Other integrated features in our conventional wellheads include hydraulic operator, gate valve, rod clamp, injection/instrumentation exits, and dual completions.

Sweet service wellhead trim comprises a set of valves and fittings made of materials that are compatible and ideal in low sulfur and low corrosive crude oil conditions.

Designed and manufactured with materials that can withstand the highly corrosive nature of crude oil or gas that contains high levels of hydrogen sulfide (H2S) or carbon dioxide (CO2).

CO2 wellhead trim is necessary in wells that produce high levels of CO2, which can cause corrosion in metal equipment and piping if not properly handled. The trim is designed to regulate the flow of fluids from the well and prevent leaks and other safety hazards associated with CO2.

Designed to regulate the flow of water injected into the reservoir to maintain pressure and displace oil towards producing wells. Can include a variety of valves and fittings such as injection valves, chokes, and flow meters to control the rate and volume of water injected into the well.

Corrosion resistant alloys (CRA) wellhead trim refers to a set of valves and fittings that are designed and manufactured using special alloys that offer high resistance to corrosion in harsh operating environments. These alloys are specifically formulated to withstand the corrosive effects of various fluids such as sour crude oil, brine, acidic gases, and other corrosive substances that are commonly encountered in the oil and gas industry. CRA wellhead trim is particularly important in sour gas or oil wells, where the presence of hydrogen sulfide (H2S) and carbon dioxide (CO2) can cause severe corrosion and material degradation. The use of CRA wellhead trim helps to extend the service life of the equipment, reduce maintenance costs, and improve operational efficiency and safety.

The casing head provides a connection point for other wellhead equipment such as blowout preventers (BOP), production trees, and casing hangers. It also provides a means of monitoring and controlling pressure in the annulus between the casing and the wellbore.

Casing hangers are used to support and suspend the casing string inside the wellbore. They are typically installed on top of the casing head and consist of a hanger assembly that is designed to fit into the wellhead and support the weight of the casing.

Primary packoffs are installed in a groove or recess in the wellhead or casing hanger and are compressed against the casing or tubing string to form a seal. They provide the initial line of defense against fluid migration or leakage from the wellbore and are designed to prevent the release of hydrocarbons, gas, or other fluids into the environment.

Secondary packoffs are backup sealing systems used in wellhead equipment to provide additional protection against fluid migration or leakage from the wellbore. They are usually employed in conjunction with primary packoffs.

Tubing heads support and suspend the production tubing that conveys oil or gas from the wellbore to the surface. Tubing heads are installed on top of the casing hanger and consist of a hanger assembly that is designed to fit into the wellhead and support the weight of the production tubing.

Tubing hangers aid in supporting and suspending the production tubing that transports oil or gas from the wellbore to the surface. Generally, they are installed on top of the tubing head and consist of a hanger assembly that is designed to fit into the tubing head and support the weight of the production tubing.

Tubing head adapters connect the tubing head to the well casing. Installation occurs on top of the casing hanger and provides a transition from the casing head to the tubing head.

Specifically designed for use in wellhead equipment, these gate valves are used to control the flow of fluids from the wellbore to the surface.

A composite pumping tree controls the production of oil or gas from a wellbore. A CPT is typically installed on top of the tubing head and consists of a tree-like structure that provides a means for controlling the flow of fluids from the wellbore.

This website uses cookies that recognize your computer or device to give you the best user experience and to improve its features. You can disable cookies through your browser but some features of the site will no longer be available. Read our Website Privacy Statement.