Highlights:

Reduced height = smaller footprint and cost savings

Offline cementing enables faster well completion

Quick-connects and torque tools streamline make-up and testing

See the DMLX-S system come to life through Stream-Flo’s guided 3D Virtual Stack-Up Experience.

Our team uses a real-time simulation to walk you through a complete installation — including assembly, offline cementing, and running tools — so you can understand how the system integrates with your operations.

This private demonstration helps your team save time, plan ahead, and make informed technical decisions — all without a field setup.

Key Benefits:

Exclusive, engineer-guided experience

Real-time 3D visualization of your full installation

Includes offline cementing, running tools, and assembly steps

Saves time and cost by allowing virtual pre-planning

Controlled access ensures proprietary system details remain secure

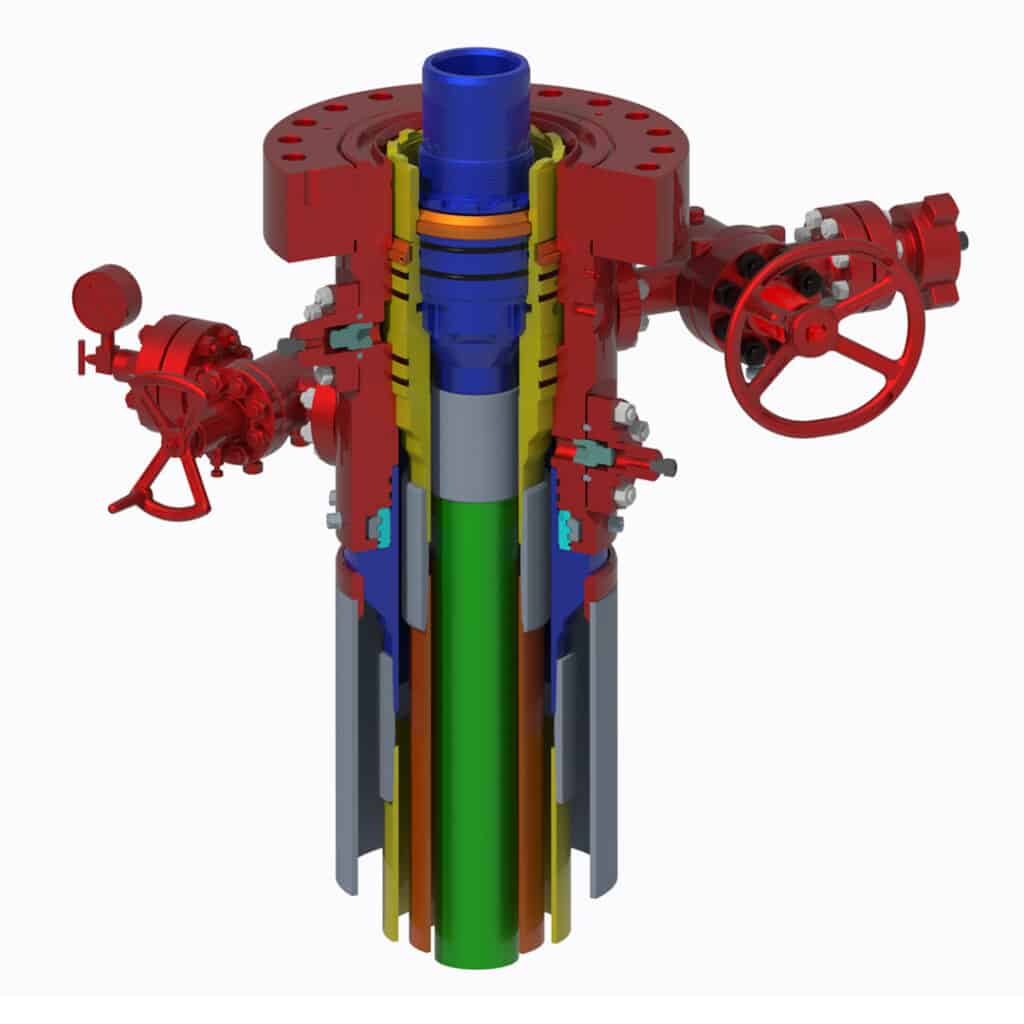

From solid to fluted to contingency mandrels, the DMLX-S provides seamless adaptability across a range of applications.

Standardized, torque-through components simplify operations and inventory management, while maintaining Stream-Flo’s reputation for reliability and integrity.

Options Include:

Fluted Mandrel: Full annular cement returns and pressure balance

Solid Mandrel: One-trip seal with torque-through rotation

Contingency Mandrel: Backup for emergency or TD challenges

With internal latch design, metal-to-metal CSBS sealing, and fully torque-through mandrel hangers, the DMLX-S maintains integrity under high-pressure, high-temperature conditions.

Backed by Stream-Flo’s field service teams and engineering expertise, it’s performance you can depend on.

| Nominal Size | Nested Size | Pressure | Temp. Range | Material Class | Outlets | Seal Type |

|---|---|---|---|---|---|---|

| 11" | 9" | 5,000 psi | –50 °F to 250 °F | AA / CC / DD / FF-1.5 / HH | 2-1/16" (60° offset) | CSBS Metal-to-Metal |

| 13-5/8" | 11" | 10,000 psi | –50 °F to 250 °F | AA / CC / DD / FF-1.5 / HH | 2-1/16" (60° offset) | CSBS Metal-to-Metal |

Book a Virtual Stack-Up session with our engineering team and explore the wellhead that’s redefining speed and reliability.

We value your privacy. Your information won’t be shared with third parties. Please review our privacy policy and privacy statement.

This website uses cookies that recognize your computer or device to give you the best user experience and to improve its features. You can disable cookies through your browser but some features of the site will no longer be available. Read our Website Privacy Statement.