A ball valve is a type of quarter-turn valve that uses a spherical ball with a hole through its center to control the flow of gas or fluids. When the ball is rotated 90 degrees by a handle, gear or actuator, the hole aligns with the flow path, allowing fluid to pass through. Rotating the ball another 90 degrees so that the hole is perpendicular to the flow path stops the flow.

Key Characteristics of Ball Valves

- Quick Operation: Ball valves provide fast and easy operation with a simple quarter-turn to open or close the valve fully.

- Tight Sealing: They offer excellent sealing capabilities, ensuring zero or minimal leakage when closed.

- Durability: Made from robust materials like carbon steel, stainless steel, brass, or plastic, ball valves are durable and can handle high pressures and temperatures.

- Versatility: They can be used in various applications, including water, gas, oil, and other fluids, across multiple industries.

- Minimal Pressure Drop: When fully open, ball valves allow a straight-through flow with minimal resistance, resulting in a low pressure drop.

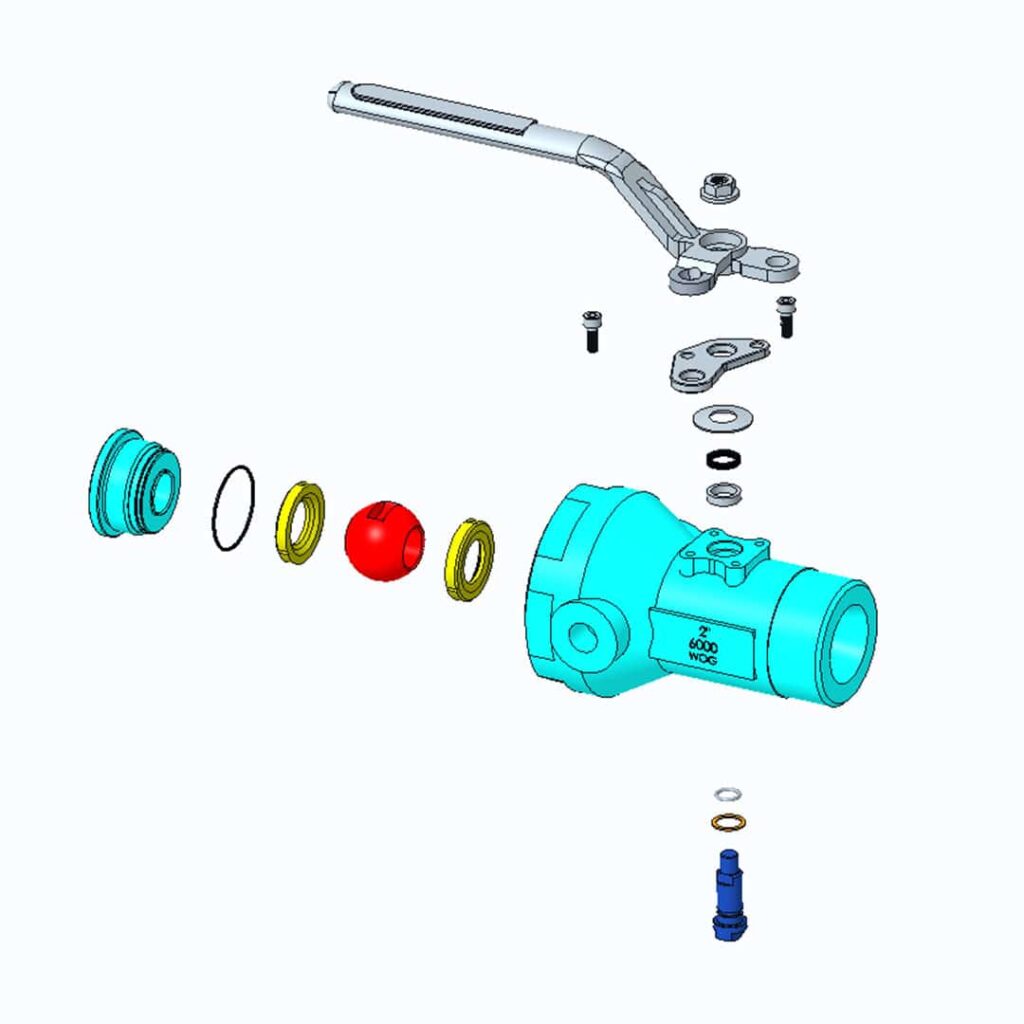

Components of a Ball Valve

- Body: The main structure that houses all the internal components.

- Ball: A spherical component with a hole through its center that controls fluid flow.

- Seat: The sealing surface against which the ball sits to stop flow.

- Stem: A shaft that connects the ball to the handle or actuator, allowing for the rotation of the ball.

- Handle or Actuator: The mechanism used to turn the ball, which can be a manual lever, gear or an automated actuator (pneumatic, hydraulic or electric).

- Seals and Gaskets: Components that ensure leak-tight connections between the valve body and other parts.

An exploded view of a Stream-Flo 317 isolator threaded ball valve.

Ball Valve Applications

- Industrial: Used in chemical processing, oil and gas, power generation, and manufacturing for on/off control of various fluids.

- Commercial: Found in HVAC systems, water supply networks, and gas pipelines.

- Residential: Commonly used in plumbing systems for water and gas control.

Types of Ball Valves

- Standard (Two-Way) Ball Valve: The most common type, with two ports (inlet and outlet).

- Three-Way Ball Valve: Has three ports and can be configured for flow diversion or mixing.

- Four-Way Ball Valve: Features four ports and is used for complex flow patterns, metering and control.

- V-Port Ball Valve: Has a V-shaped ball or seat for more precise flow control.

- Trunnion Ball Valve: Designed for high-pressure applications, with additional support for the ball to reduce operating torque.

An exploded view highlighting the seats and seals of a Stream-Flo trunnion ball valve.

In short, a ball valve is a versatile and reliable valve used in various piping systems to provide quick and effective control of fluid flow vs. multi-turn valves such as gate valves.

Are ball valves commonly used in oil and gas?

Yes, ball valves are widely used in the oil and gas industry due to their reliability, durability, and ability to provide tight sealing. Here are some key reasons and applications for oil and gas ball valves:

Reasons for Use

- Tight Sealing: Ball valves provide a reliable seal, preventing leaks and ensuring the integrity of the system, which is crucial in handling hydrocarbons and other hazardous substances.

- Durability: Made from robust materials such as stainless steel, carbon steel, and other corrosion-resistant alloys, ball valves can withstand the harsh conditions typical of oil and gas operations, including high pressures and extreme temperatures.

- Quick Operation: The quarter-turn operation allows for fast opening and closing, which is essential for emergency shut-off and quick isolation of system sections vs. multi-turn valves such as gate valves.

- Low Maintenance: Ball valves have a simple design with fewer moving parts, resulting in lower maintenance requirements and longer service life.

- Versatility: They can handle a wide range of fluids, including crude oil, natural gas, refined products, and other process fluids.

Oil and gas ball valve applications

- Pipeline Systems: Ball valves are used to control the flow of crude oil, natural gas, and refined products in pipelines, providing shut-off and flow regulation.

- Storage Facilities: They are installed in storage tanks and terminals to manage the transfer of oil and gas products and ensure safe isolation during maintenance and emergencies.

- Processing Plants: In refineries and gas processing plants, ball valves control the flow of various process streams, including feedstocks, intermediates, and finished products.

- Offshore Platforms: Used in offshore drilling and production platforms, ball valves control wellhead equipment, subsea systems, and production pipelines.

- Metering Stations: Ball valves are employed in metering and measurement stations to ensure accurate flow control and isolation during maintenance.

- Safety Systems: In emergency shutdown (ESD) systems, ball valves provide quick and reliable shut-off to prevent accidents and contain spills.

- High-Pressure Applications: Trunnion-mounted ball valves and other specialized designs are used in high-pressure systems, such as wellheads and injection lines, to ensure safe and reliable operation.

Types of Ball Valves Used

Floating Ball Valves: Suitable for low to medium pressure applications, with the ball floating in the valve body and sealing against seats on either side.

A Stream-Flo flanged floating ball valve.

Trunnion-Mounted Ball Valves: Designed for high-pressure applications, with the ball supported on an axis by trunnions (pivot points) to reduce operating torque and improve sealing.

A Stream-Flo trunnion ball valve.

Top-Entry Ball Valves: Allow for easy maintenance and repair without removing the valve from the pipeline, often used in critical or remote applications.

Fully Welded Ball Valves: Provide enhanced sealing and strength for underground applications, minimizing the risk of leaks.

Socket Welded Ball Valves: Feature standard cooling “fins” allowing valves to be welded inline without disassembly, saving operational time and providing greater ease of use.

A Stream-Flo socket weld ball valve.

Metal-Seated Ball Valves: Used in high-temperature and abrasive service conditions where soft seats would fail.